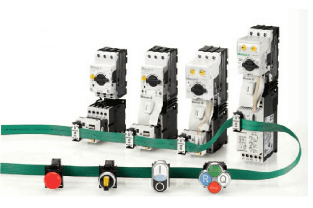

Eaton Industrial Switchgear

CI-K5-125-M

Enclosure, insulated + mtg plate

Trade Price

£80.61

Per

1

Unit

EACH

Pack Quantity

1

Information

Eaton Moeller® series CI-K Insulated enclosure, HxWxD=280x200x125mm, +mounting plate

Technical Specifications

Product Length/Depth

280 mm

Product Height

125 mm

Product Width

200 mm

Product Weight

1.33 kg

Certifications

IEC/EN 60529

IEC 60068-2-11

UL94: HB

UL94: VO/1.5 mm thickness

DIN EN 62208

Catalog Notes

Lamp indicator L‐… can be mounted in base knock-out M20/M25

Enclosure color

Light gray, Cover (RAL 7035)

Light gray, Operator (RAL 7035)

Black (RAL 9005)

Enclosure material

1 Ω x 10¹³ (Surface resistance to IEC 60093)

Plastic

Features

Halogen free

UV resistance beneath protective shield

Fitted with:

Control cable entry

DIN-rail

Weight of fitted components: max. 1.7 kg

Knockouts

Metric cable entry knockouts at the top, bottom and back plate

Hard knockout version

Cover material

Glass-fiber reinforced polycarbonate

Degree of protection

IP65

NEMA Other

Degree of protection (front side)

IP65

Dielectric strength

30 kV/mm, according to IEC 60243-1

Flammability characteristics

960 °C/1 mm thickness (base, cover; glow wire to VDE 0471 Part 2)

650 °C/1 mm thick (push-through membrane) to VDE 0471 Part 2)

Model

Surface mounting

Mounting depth

98 mm

Mounting weight capacity - max

1 kg

Product category

Empty enclosures

Suitable for

Emergency stop

Surface treatment

Resistant to corrosion

Track resistance

CTI 175 (base, to IEC 60112)

CTI 175 (cover, to IEC 60112)

Type

Basic enclosure

Water consumption

0.29 % (According to DIN EN ISO 62)

Environmental resistance

Partly resistant to alcohol

Partly resistant to benzene

Resistant against gasoline

Resistant against greases

Chemical resistant (Base, Cover)

Not resistant to alkalis

Partly resistant to greases

Resistant against benzene

Not resistant to Mineral oil

Chemical resistant (Push-through membrane (CI-K1/CI-K2) and sealing material)

Resistant against alkalis

Not resistant to benzene

Partly resistant to acids (> 10%)

Resistant against alcohol

Resistant against salt solutions

Resistant against acids (< 10%)

Resistant against mineral oil

Impact resistance

IK06 (according to EN 50102)

Temperature resistance

-40 - 120 °C (enclosure)

-40 - 80 °C (gasket)

Ambient operating temperature - min

-25 °C

Ambient operating temperature - max

70 °C

Climatic proofing

Damp heat, cyclic, to IEC 60068-2-30

Damp heat, constant, to IEC 60068-2-78

Equipment heat dissipation, current-dependent Pvid

0 W

Heat dissipation capacity Pdiss

35 W

Heat dissipation per pole, current-dependent Pvid

0 W

Rated operational current for specified heat dissipation (In)

0 A

Static heat dissipation, non-current-dependent Pvs

0 W

Radiated heat dissipation with separate mounting

35 W (at an ambient temperature of 20 °C)

10.2.2 Corrosion resistance

Meets the product standard's requirements.

10.2.3.1 Verification of thermal stability of enclosures

Meets the product standard's requirements.

10.2.3.2 Verification of resistance of insulating materials to normal heat

Meets the product standard's requirements.

10.2.3.3 Resist. of insul. mat. to abnormal heat/fire by internal elect. effects

Meets the product standard's requirements.

10.2.4 Resistance to ultra-violet (UV) radiation

Please enquire

10.2.5 Lifting

Not applicable.

10.2.6 Mechanical impact

Does not apply, since the entire switchgear needs to be evaluated.

10.2.7 Inscriptions

Meets the product standard's requirements.

10.3 Degree of protection of assemblies

Meets the product standard's requirements.

10.4 Clearances and creepage distances

Meets the product standard's requirements.

10.5 Protection against electric shock

Does not apply, since the entire switchgear needs to be evaluated.

10.6 Incorporation of switching devices and components

Does not apply, since the entire switchgear needs to be evaluated.

10.7 Internal electrical circuits and connections

Is the panel builder's responsibility.

10.8 Connections for external conductors

Is the panel builder's responsibility.

10.9.2 Power-frequency electric strength

Is the panel builder's responsibility.

10.9.3 Impulse withstand voltage

Is the panel builder's responsibility.

10.9.4 Testing of enclosures made of insulating material

Meets the product standard's requirements.

10.10 Temperature rise

The panel builder is responsible for the temperature rise calculation. Eaton will provide heat dissipation data for the devices.

10.11 Short-circuit rating

Is the panel builder's responsibility. The specifications for the switchgear must be observed.

10.12 Electromagnetic compatibility

Is the panel builder's responsibility. The specifications for the switchgear must be observed.

10.13 Mechanical function

The device meets the requirements, provided the information in the instruction leaflet (IL) is observed.

Document Links

Datasheet