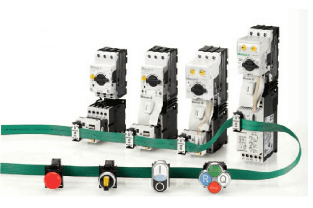

Eaton Industrial Switchgear

PKE32/XTU-32

PKE complete device (standard) 8-32 A

Trade Price

£200.76

Per

1

Unit

EACH

Pack Quantity

1

Information

Eaton Moeller® series PKE32 Motor-protective circuit-breaker, Complete device with standard knob, Electronic, 8 - 32 A, 32 A, With overload release, Screw terminals

Technical Specifications

Product Length/Depth

101 mm

Product Height

102.5 mm

Product Width

45 mm

Product Weight

0.436 kg

Certifications

CE

CSA

IEC/EN 60947-4-1

IEC/EN 60947

CSA Class No.: 3211-05

CSA File No.: 165628

CSA-C22.2 No. 60947-4-1-14

UL

UL File No.: E36332

UL Category Control No.: NLRV

VDE 0660

UL 60947-4-1

Actuator type

Turn button

Features

Phase-failure sensitivity (according to IEC/EN 60947-4-1, VDE 0660 Part 102)

Fitted with:

Standard knob

Functions

Motor protection for heavy starting duty

Motor protection

Overload release

Number of poles

Three-pole

Current flow times - min

700 (Class 10) AC-4 cycle operation, Main conducting paths

900 (Class 15) AC-4 cycle operation, Main conducting paths

For all combinations with an SWD activation, you need not adhere to the minimum current flow times and minimum cut-out periods.

500 (Class 5) AC-4 cycle operation, Main conducting paths

1000 (Class 20) AC-4 cycle operation, Main conducting paths

Note: Going below the minimum current flow time can cause overheating of the load (motor).

Cut-out periods - min

<= 500 ms, main conducting paths, AC-4 cycle operation

Degree of protection

Terminals: IP00

IP20

Lifespan, electrical

50,000 operations (at 400V, AC-3)

Lifespan, mechanical

50,000 Operations (Main conducting paths)

Operating frequency

60 Operations/h

Overload release current setting - min

32 A

Overload release current setting - max

32 A

Overvoltage category

III

Pollution degree

3

Product category

Motor protective circuit breaker

Protection

Finger and back-of-hand proof, Protection against direct contact when actuated from front (EN 50274)

Rated impulse withstand voltage (Uimp)

6000 V AC

Suitable for

Also motors with efficiency class IE3

Temperature compensation

-25 - 55 °C, Operating range

-5 - 40 °C to IEC/EN 60947, VDE 0660

Shock resistance

25 g, Mechanical, according to IEC/EN 60068-2-27, Half-sinusoidal shock 10 ms

Altitude

Max. 2000 m

Ambient operating temperature - min

-25 °C

Ambient operating temperature - max

55 °C

Ambient operating temperature (enclosed) - min

25 °C

Ambient operating temperature (enclosed) - max

40 °C

Ambient storage temperature - min

40 °C

Ambient storage temperature - max

80 °C

Climatic proofing

Damp heat, cyclic, to IEC 60068-2-30

Damp heat, constant, to IEC 60068-2-78

Terminal capacity (flexible with ferrule)

1 x (1 - 6) mm², ferrule to DIN 46228

2 x (1 - 6) mm², ferrule to DIN 46228

Terminal capacity (solid)

2 x (1 - 6) mm²

1 x (1 - 6) mm²

Terminal capacity (solid/stranded AWG)

14 - 10

Stripping length (main cable)

10 mm

Tightening torque

1.7 Nm, Screw terminals, Main cable

1 Nm, Screw terminals, Control circuit cables

Rated frequency - min

50 Hz

Rated frequency - max

60 Hz

Rated operational current (Ie)

32 A

Rated operational power at AC-3, 220/230 V, 50 Hz

7.5 kW

Rated operational power at AC-3, 380/400 V, 50 Hz

15 kW

Rated operational voltage (Ue) - min

690 V

Rated operational voltage (Ue) - max

690 V

Rated uninterrupted current (Iu)

32 A

Short-circuit current rating (group protection)

100 kA, 600 V High Fault, Fuse, SCCR (UL/CSA)

100 A, Class J, 600 V High Fault, max. Fuse, SCCR (UL/CSA)

Short-circuit release

Trip block fixed 15.5 x Ir

Delayed approx. 60 ms, Trip blocks

Basic device fixed 15.5 x Iu, Trip Blocks

± 20% tolerance, Trip blocks

Switching capacity

32 A, General use UL/CSA

32 A, AC-3 up to 690 V

Assigned motor power at 115/120 V, 60 Hz, 1-phase

1.5 HP

Assigned motor power at 200/208 V, 60 Hz, 3-phase

5 HP

Assigned motor power at 230/240 V, 60 Hz, 1-phase

3 HP

Assigned motor power at 230/240 V, 60 Hz, 3-phase

7.5 HP

Assigned motor power at 460/480 V, 60 Hz, 3-phase

15 HP

Assigned motor power at 575/600 V, 60 Hz, 3-phase

20 HP

Connection

Screw terminals

Equipment heat dissipation, current-dependent Pvid

11.4 W

Heat dissipation capacity Pdiss

0 W

Heat dissipation per pole, current-dependent Pvid

3.8 W

Rated operational current for specified heat dissipation (In)

32 A

Static heat dissipation, non-current-dependent Pvs

0 W

10.2.2 Corrosion resistance

Meets the product standard's requirements.

10.2.3.1 Verification of thermal stability of enclosures

Meets the product standard's requirements.

10.2.3.2 Verification of resistance of insulating materials to normal heat

Meets the product standard's requirements.

10.2.3.3 Resist. of insul. mat. to abnormal heat/fire by internal elect. effects

Meets the product standard's requirements.

10.2.4 Resistance to ultra-violet (UV) radiation

Meets the product standard's requirements.

10.2.5 Lifting

Does not apply, since the entire switchgear needs to be evaluated.

10.2.6 Mechanical impact

Does not apply, since the entire switchgear needs to be evaluated.

10.2.7 Inscriptions

Meets the product standard's requirements.

10.3 Degree of protection of assemblies

Does not apply, since the entire switchgear needs to be evaluated.

10.4 Clearances and creepage distances

Meets the product standard's requirements.

10.5 Protection against electric shock

Does not apply, since the entire switchgear needs to be evaluated.

10.6 Incorporation of switching devices and components

Does not apply, since the entire switchgear needs to be evaluated.

10.7 Internal electrical circuits and connections

Is the panel builder's responsibility.

10.8 Connections for external conductors

Is the panel builder's responsibility.

10.9.2 Power-frequency electric strength

Is the panel builder's responsibility.

10.9.3 Impulse withstand voltage

Is the panel builder's responsibility.

10.9.4 Testing of enclosures made of insulating material

Is the panel builder's responsibility.

10.10 Temperature rise

The panel builder is responsible for the temperature rise calculation. Eaton will provide heat dissipation data for the devices.

10.11 Short-circuit rating

Is the panel builder's responsibility. The specifications for the switchgear must be observed.

10.12 Electromagnetic compatibility

Is the panel builder's responsibility. The specifications for the switchgear must be observed.

10.13 Mechanical function

The device meets the requirements, provided the information in the instruction leaflet (IL) is observed.

Document Links

Datasheet